Energy Research Park Renovation (ERP)

University of Houston

Shah Smith & Associates, Inc. was part of the architect/engineer team that provided programming, design, and construction administration services that transformed a 70 acre campus with 15 buildings into a destination for energy related translational research collaboration between university researchers and industry. The project site, Energy Research Park, was acquired by the University of Houston in Summer of 2009. The ERP campus, 5000 Gulf Freeway, is located ½ mile East of the main campus and comprises 14 office and office/warehouse buildings, constructed between 1953 and 1982. The cumulative buildings enclose 580,552 SF of space.

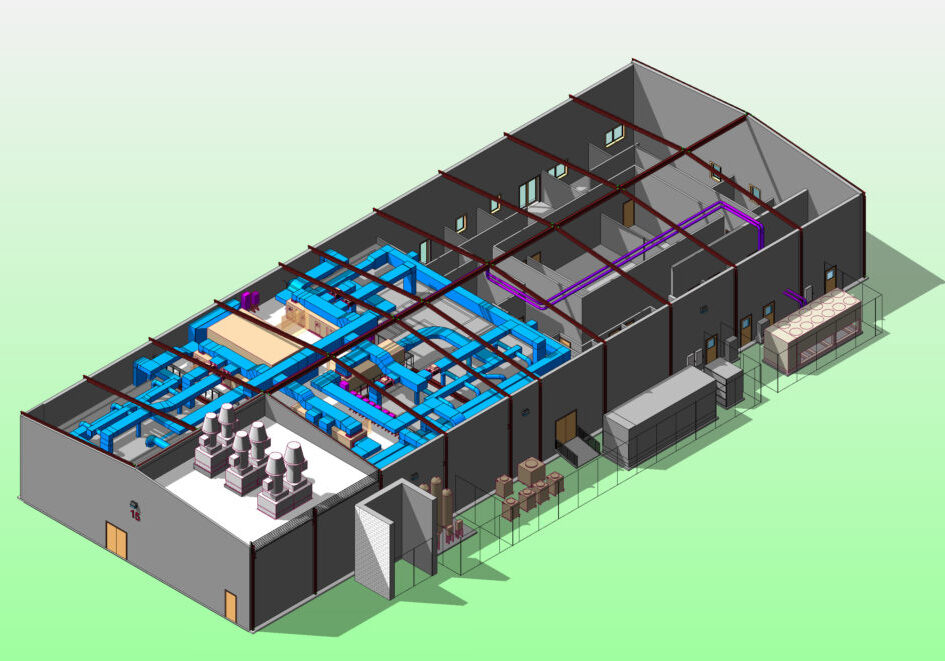

SSA’s initial scope of services include existing building assessment of mechanical, electrical, and plumbing utilities, initial tenant MEP space and lab programming, and “test fit” prospective tenants in available space for establishing order of magnitude cost impact to upgrade/replace MEP systems to meet tenant needs. New tenant projects included a new Petroleum Engineering Department (bldg. 9), a commercial joint venture for manufacturing a lightweight superconducting high voltage transmission wire (bldg. 14), relocating the main campus machine and carpentry shops to this campus (bldg. 7), and a new cutting edge research lab looking into improving solar panel efficiency with superconductivity advances (bldg. 15). SSA also produced CDs for a Wind Energy Test Equipment facility (bldg.. 13), and a conceptual/schematic design for renovating bldg 7 for structural beam and wind turbine blade failure testing. The design team worked with Construction Managers at Risk to provide early construction documentation for long lead MEP equipment.

Building 9 with Petroleum Engineering Department as tenant, project included classroom, Computer Visualization Lab, Production Fluids Lab, Rock Properties lab, Mud lab, Teaching and graduate research labs.

Building 7, campus machine and carpentry shops, renovated industrial space into separate flexible machine shop space and a carpentry shop. The machine shop includes CNC, lathes, drill press, grinders, welding areas with hood, metal press, and numerous other metal forming equipment. The area was served by overhead electrical busbar for power and piped with shop air.

Building 15, Energy Device Fabrication Lab, project includes semi-clean room space for device fabrication, a MEP equipment mezzanine for accessibility outside the process and clean areas, testing and characterization labs, lithography lab, and shop space for equipment support. There is a separate toxic gas storage room with explosion venting, an exterior equipment yard. Process gasses include Silane, Phosphine, Arsine, Diborane, Germane, Hydrogen, Ammonia, Nitrogen, Argon, and compressed lab air.

Building 13, Wind Energy Test Equipment Facility, was a new stand alone high bay prefabricated metal building with a strong floor, perimeter trench drain for routing hydraulic lines, and low bay equipment rooms and support spaces.

Building 7, structural beam and wind turbine blade failure testing project renovated an existing high/low bay industrial building with drive thru feature in the high bay area to include a strong floor for failure testing both concrete bridge abutments and 75 meter wind turbine blades, 5 and 10 ton overhead traveling cranes, vibration testing lab for wind turbine blades, metallurgy and diagnostic testing support labs, fiberglass wind turbine blade fabrication shops, hydraulic equipment space, and an environmental chamber for rapid thermal cycling of 10 meter wind turbine blades.

Site Owner

Location

Project Cost

$20,000,000

Project Completion

2013

Expertise

Higher Education

Research

Science and Technology

Services

Electrical Engineering

Mechanical Engineering

Plumbing Engineering